Choosing the RAW MATERIALS is a key element in the production process. Solid wood and veneers, chosen according to COLOR and GRAIN, are selected directly from the most qualified suppliers. Also wood-based panels (blockboard, plywood, etc.), used according to the characteristics of STABILITY and LIGHTWEIGHT that the final piece is required to have, are selected at source.

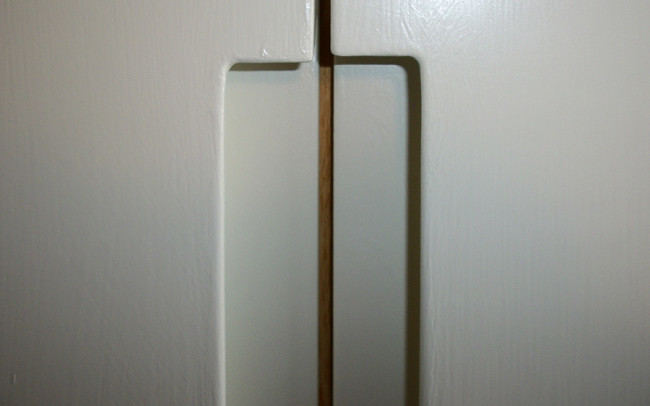

Surface finishings are the element closest to the piece’s final user, together with the material, they constitute the “SENSITIVE SURFACE” that is the point of contact between man and his environment. The type of finishing, sanding, or the brush treatment, together with the wood’s natural grain, are altogether the features that go into making the MATERIALITY of the finished product.

Nowadays, it is ever more common to treat wood naturally, that is with light coverage using rather porous finishings such as OILS and WAXES. Or with finishings that allow a variable intensity of coverage and different cleanability, water or acrylic-based VARNISHES, transparent or bleached, matte or glossy.

LACQUERS have always been a precious finishing material and can be applied by hand with brush or tampon, or by uniform spray systems, with varying degrees of gloss and brilliance. COLOUR is the feature that can always be customised and adapted to the environment one wishes to create.